CNC Series JMNC43A+EP50+D43

- Specs

- Accessories

- Features

- Controls

- Cut Samples

- Video

- Inquiry

MACHINE UNIT & DIELETRIC TANK UNIT

| ITEM | UNIT | JMNC43A+EP50+D43 |

|---|---|---|

| Work table size | mm | 650 × 400 |

| X travel | mm | 400 |

| Y travel | mm | 300 |

| Z travel | mm | 350 |

| Ram platen to work table | mm | 290 ~ 640 |

| Max. electrode weight | kgs | 75 |

| Max. workpiece weight | kgs | 800 |

| Work tank ( W × D × H) | mm | 1080 × 560 × 340 |

| Weight of machine unit | kgs | 1400 |

| Machine Outside dimensions ( W × D × H ) | mm | 1480 × 1900 × 2340 |

| Max. Machining Current | A | 50 |

| Total Power Input | KVA | 4.5 |

| Max. Metal Removal Rate | mm3 / min | 390 |

| Electrode Wear Ratio | % | 0.2 |

| Best Surface Roughness | µm Ra | 0.2 |

| Net Weight | kgs | 320 |

| Outside Dimensions ( W × D × H ) | mm | 680 × 1070 × 1820 |

| Dielectric tank capacity | L | 320 |

| Dielectric tank pump | HP | 0.5 HP × 1 |

| Dielectric tank net weight | kgs | 100 |

| Dielectric tank filter method | Paper filter | |

| Dielectric tank outside dimensions ( W × D × H ) | mm | 850 × 1150 × 1000 |

* All specification and design are subject to change without notices.

STANDARD ACCESSORIES

| Paper filters 1 set |

| Tool box 1 pc |

| Flushing nozzle 1 set |

| Drill chuck 1 pc |

| Clamping kit 1 set |

| Electrode holder 1 pc |

| Halogen machine work lamp 1 pc |

| Leveling pads 1 set |

| Linear scale ( installed on machine ) 1 set |

OPTIONAL ACCESSORIES

| Auto fire extinguisher |

| Permanent magnetic table |

| Dielectric cooler |

| Spare PCB set |

FEATURES

| Using symmetrical structure design and the castings are all made by high-strength cast iron and being annealed with high rigidity and well-balanced thermal stability. |

| Using high-precision ball-screw on each axis, some use bigger location pin and with pretension design. Therefore, it has great characteristics on positioning accuracy, machine rigidity and motion. |

| Using high-precision and gapless ball / roller guide way on each axis, provide high-precision motion |

| guidance. |

| Using precise wide angular ball bearings on each axis to ensure the required loads for axial and radial, providing the running smoothness and accuracy when machining. |

| The surface of work table has been hardened and grinding treatment, with excellent abrasion resistance and improves machine life. |

| Using high-resolution linear scales on each axis, to ensure the accuracy under static and dynamic |

| condition. |

| The advanced transmission mechanism for each axis, to improve the efficiency, stability and accuracy when machining. |

| Adopt the electromagnetic brake on Z-axis, to offer its function instantly. |

| Using high-capacity lubricator, with efficient lubricating loop, providing a reliable lubricant supply for each axis, to enhance the life-time of mechanical parts. |

| Using full-covered protective structure for each axis, to ensure operator’s safety and to prevent dust or liquid falling into the machine. |

| With both oil flushing and suction devices on work tank and work head, to offer a convenient way for different kind of workpieces application. |

| The dielectric level in the work tank is controlled by stepless feature, to provide efficient speed to the expected dielectric height. |

| Work tank drain system uses a larger diameter drain device, dielectric can be processed into the dielectric tank in a very short time. |

| Use a high flow rate PUMP, to fill up the dielectric in the work tank within a very short time. |

| Labyrinth compartment design in the dielectric tank, which can effectively improve the cleanliness of processing dielectric. |

| Using a high efficiency paper filter for dielectric tank, to provide fast and cleaned dielectric. |

| The pressure gauge in dielectric tank, provides instant information for normal flow of dielectric in the filtration system and in the pipelines. |

| Some models equipped with high loading capacity wheels for easy movement of dielectric tanks, as well as provide convenience for maintenance or cleaning of the tank. |

| A simple configuration for Machine body, Generator and Dielectric tank, to reduce the floor space and easy for maintenance purpose. |

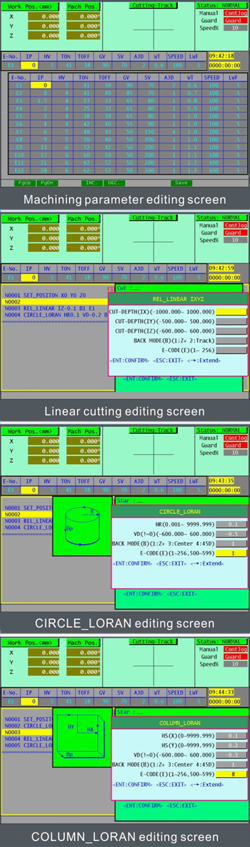

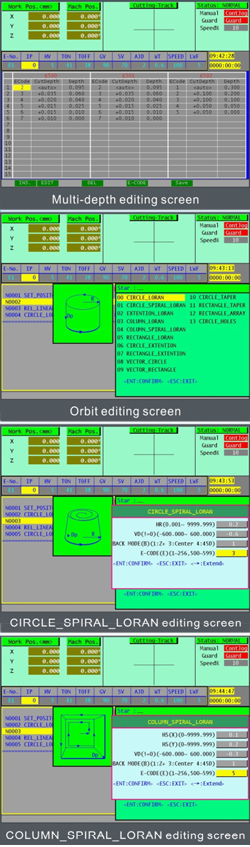

CNC EDM CONTROL FEATURES

| EP CNC EDM CONTROLER is a PC-BASED CNC controller. |

| The Graphic-User-Interface uses industrial-grade 486-PC architecture. |

| The closed-loop servo control is by the high speed 32 bits DSP processor, and achieve the best efficiency discharge machining and high accuracy. |

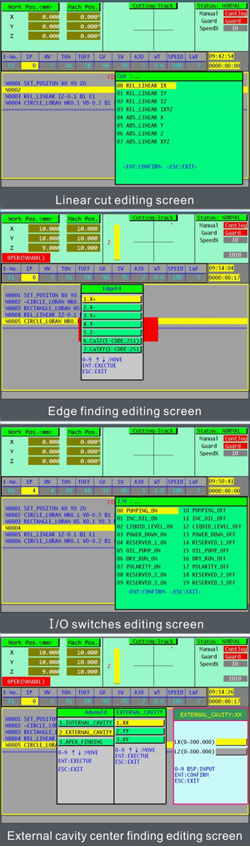

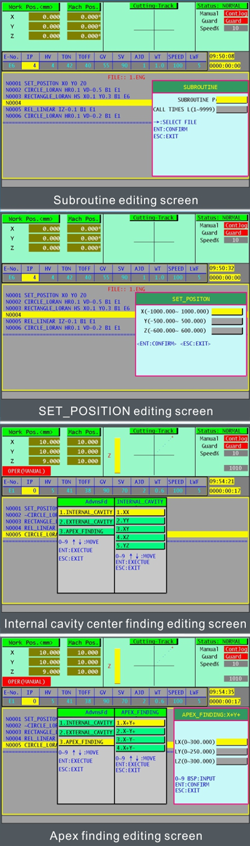

| Intuitive graphics / Several orbit cutting / Multi-depth cutting / Simulation-cutting / Multi-Area mark line cutting / Skip line / Software-Protect-Limit, these provide a substantial increase in the efficiency of programming and to avoid causing mistakes. |

| Provide comment line functions and common word input, USB files import / export, you can put the project information to achieve the project management and the effectiveness of the memorandum. |

SOFTWARE SPECIFICATION :

| Language : English / Chinese |

| Unit : British system ( inch ) / Metric system ( mm ) |

| Coordinate : Machine Coordinate / Working Coordinate |

| Jogging Mode : Continuous / Increase / No Guard |

| JOG Speed : 1∕10∕100μm |

| File Maximum Lines : 1000 Lines |

| Subroutine-Level : Maximum 5 Levels |

| Program Edit : Dialog programming ( Range Prompt & Check ) |

| Files Import / Export : USB Disk ( FAT32 / FAT16 ) |

| Finding Function : Home / Edge / Internal_Cavity / External_Cavity / Apex / Sparkle Tooling Correction |

| Positioning : Mechanical Position, Working Position, Set Position, 1/2 XY |

| Cutting Function : XYZ Linear / Orbit / Cone / Loran / Vector / Extension / Circle-Holes / Array-Cut |

| E-Code Number : 256 set |

| Multi-Depth-Cutting : Maximum 100 Groups, 15 Depths per Group. |

| Cutting Mode : Simulation-Run / Multi-Mark-Cutting / Line-Skip / Normal-Cutting |

| Provide Software-Protect-Limit Function & Enabled / Disabled. |

| Private Remark Line & User-Defined-Word. |

| Help function. |

HARDWARE SPECIFICATION :

| POWER : AC 100V ~ 240V ( 50Hz / 60Hz ) |

| CPU : Industrial Grade 486 PC |

| VGA Resolution : 800 × 600 |

| Key Board : PS2 |

| Control Axes : X / Y / Z |

| Hard Disk : CF Card |

| Servo Control Board : High Speed 32 Bits DSP Closed-Loop Control |

| Digital IO : DC24V Standard DI:48 / DO:48 ( can extend ) |

| Sys-Interface Card : RS485 x 2 ( One is for USB-Disk Reader ) |

| USB Disk Reader : USB disk maximum 32GB ( USB2.0 ) |

SPARKING CIRCUIT :

| Most advanced “L.W.F” sparking circuit able to control the peak current rising slope, reduce the corner wear substanially. |

| Tracking mode OFF-TIME control circuit to prevent Arcing. |

| Using “MOSFET” sparking circuit to enhance performance. |

| All PC boards are sectioned in modular box design, reduce maintenance cost. |

| Dual voltage (High & Low voltage) currents being synchronously discharged allows faster metal removal rate and uniform surface finish. |

SYSTEM SETTING UNIT:

| Metric - Minimum : 0.001 mm / Minimum Command Value : 0.001 mm / Maximum Stroke Setting : 9999.999 mm |

| English - Minimum : 0.0001 inch - Minimum Command Value : 0.0001 inch / Maximum Stroke Setting : 999.9999 inch |