Broken Tap Remover TR100

Developed by a group of top engineers and technicians with rich on ground and theoretical experience in the field of EDM, TR100 renders superb engineering supremacy and unmatched mechanical features to outstand others.

- Specs

- Accessories

- Features

- Controls

- Cut Samples

- Video

- Inquiry

GENERATOR

| ITEM | UNIT | TR100 |

|---|---|---|

| Weight | Kgs | 17 Kgs |

| Dimensions | mm | 290 × 345 × 285 |

MACHINE UNIT

| ITEM | UNIT | TR100 |

|---|---|---|

| Weight | Kgs | 6 Kgs with magnetic stand |

| Dimensions | mm | 53 × 70 × 375 |

| Electrode Holder | mm | Max. Ø 6.5 |

* All specification and design are subject to change without notices.

STANDARD ACCESSORIES

| Generator |

| Machine unit |

| Chemical clay |

| Chuck handle |

| Brass electrode bar - Ø 1.5mm × 4PCS / Ø 2.0mm × 2PCS / Ø 2.5mm × 2PCS / Ø 3.0mm × 2PCS / Ø 4.0mm × 1PC / Ø 0.5mm × 1PC / Ø 6.0mm × 1PC |

MECHANICAL FEATURES OF TR100

| Light, small, portable, compact design. |

| High speed & high efficiency and low cost. |

| Simple operation, easily remove broken tap. |

| Full power source choices : 100V / 110V / 120V / 200V / 220V / 230V / 240V , 1 PHASE, 50HZ / 60HZ. |

| Dielectric : Using ordinary tap water as machining dielectric liquid. |

| Electrode : Using any brass bar as electrode. |

| Flexibility : Machining easily even on a large workpiece. |

| No damage : Remove taps easily without damage the threads. |

| Complete functions : Auto fed, depth setting ( stop at a specific depth ), selectable arcing timer, auto retract, workhead swivel alarm messages: depth arrival, arcing, over-temp. |

| More applications : Starting holes for Wire Cut EDM. |

| Cutting Tungsten Carbide or any harden steel. |

Control System

| 1. 8-bit single chip microcomputer control system |

| 2. 8-bit digital to analog gap voltage feedback |

| 3. The dynamic servo sensitivity controls the machining gap to achieve the best machining stability |

| 4. PWM pulse wave modulation motor drive circuit |

Cut Samples

Cut Samples

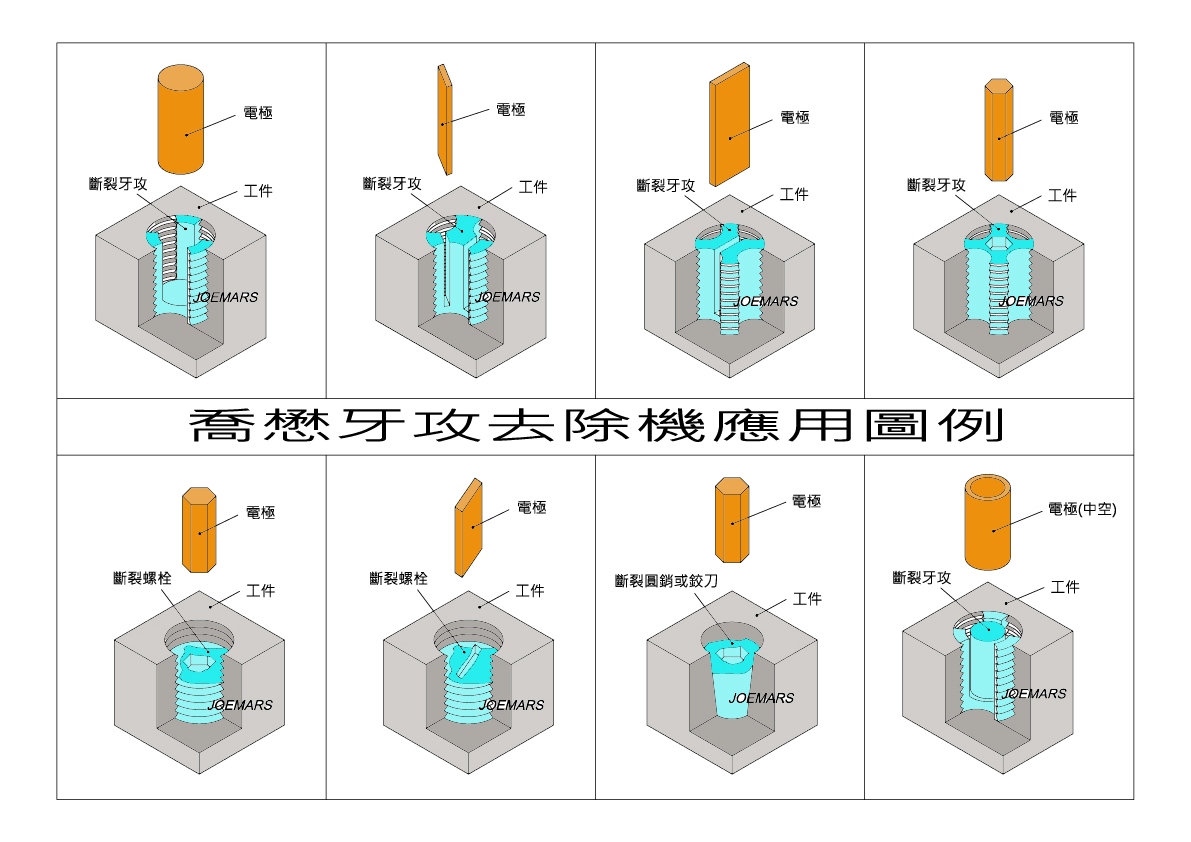

Application Legend

|